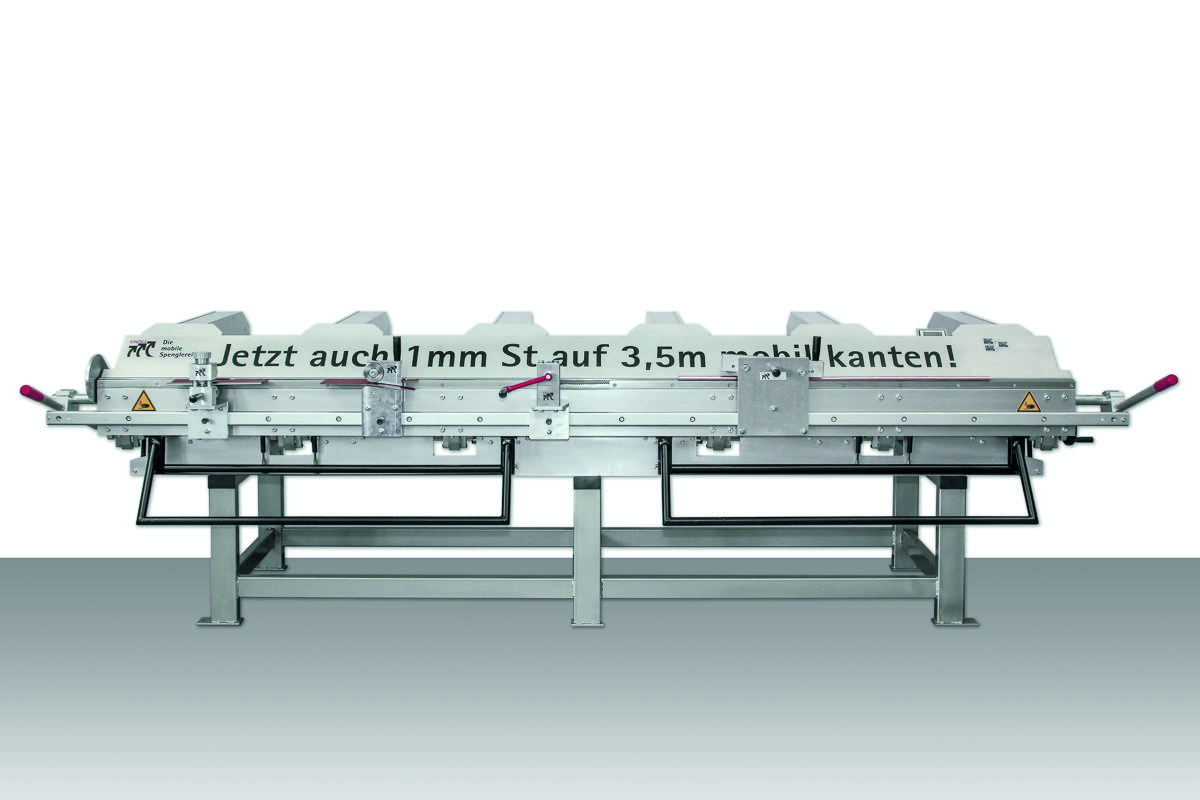

KNOLL Sheet Metal Brake C4 on optional frame.

The KNOLL Sheet Metal Brake, with folding up to 180° and 3.5m, is made of a high strength aluminum making it extremely lightweight and very stable. This brake was developed by experienced architectural sheet metal workers and has been successfully tried and tested at thousands of construction sites in Germany and abroad.

Features:

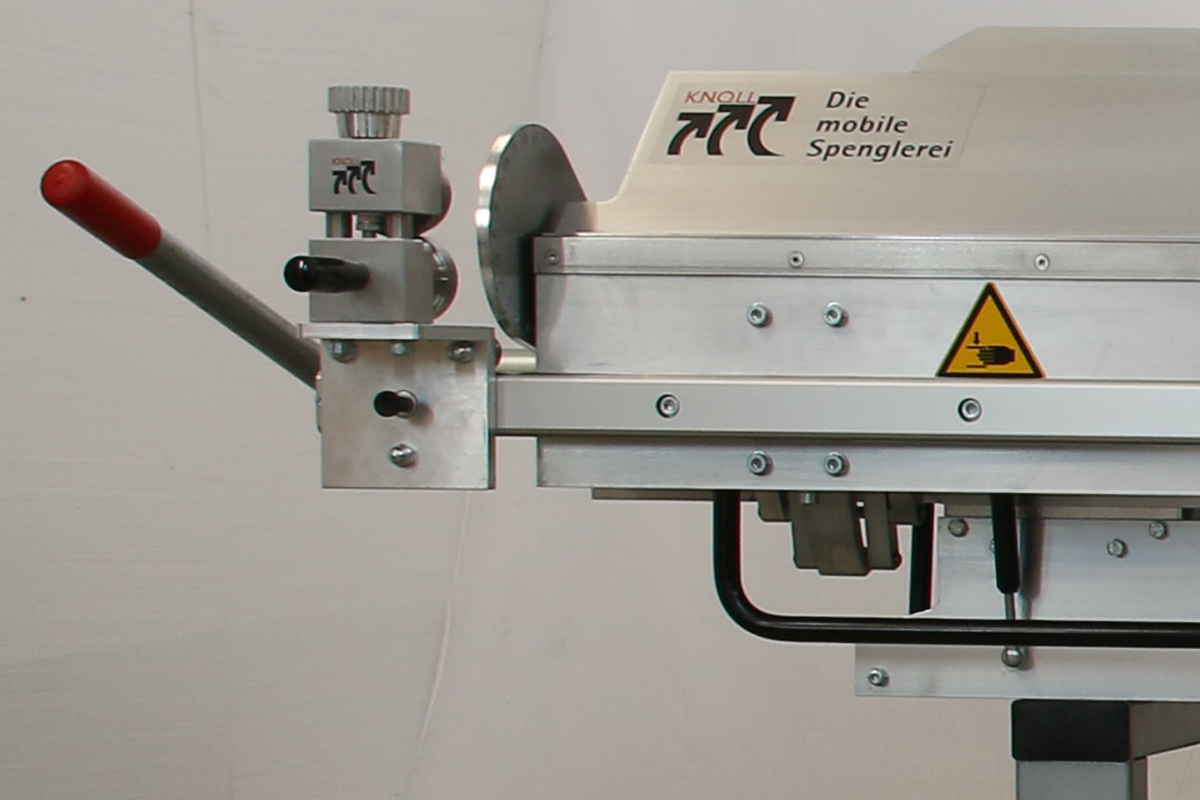

- Patented KNOLL profiling device

- KNOLL cutting device

- Guide rail with stainless steel track for profiling device, cutting device and optional accessories.

- Side mounted angle gauge, can be folded back when using longer sheets of metal

The KNOLL sheet metal brake is available in two versions to suit different applications.

The four-arm folding machine is ideal for architectural sheet metal work, with a capacity of:

-

Aluminum: 1.0 mm

-

Copper: 0.8 mm

-

Zinc: 0.8 mm

-

Steel: 0.7 mm

For those who require a more robust solution but still need mobility, the KNOLL sheet metal brake 6C is the perfect choice. Designed with reinforced joints and six C-arms, it can handle stronger materials—including steel up to 1.0 mm thick.

KNOLL Sheet Metal Brake C6 on optional frame.

Folding up to 3.5m

The KNOLL sheet metal brake is very stable. This ensures high accuracy during daily use at the construction site. The machine is open on the side, allowing for longer metal sheets to be processed. The angular graduation is folded to the back for this. On the right and left sides of the folding machine, the guide rail provides a parking position for the cutting head and the profiling head. So your tools are within reach at all times!

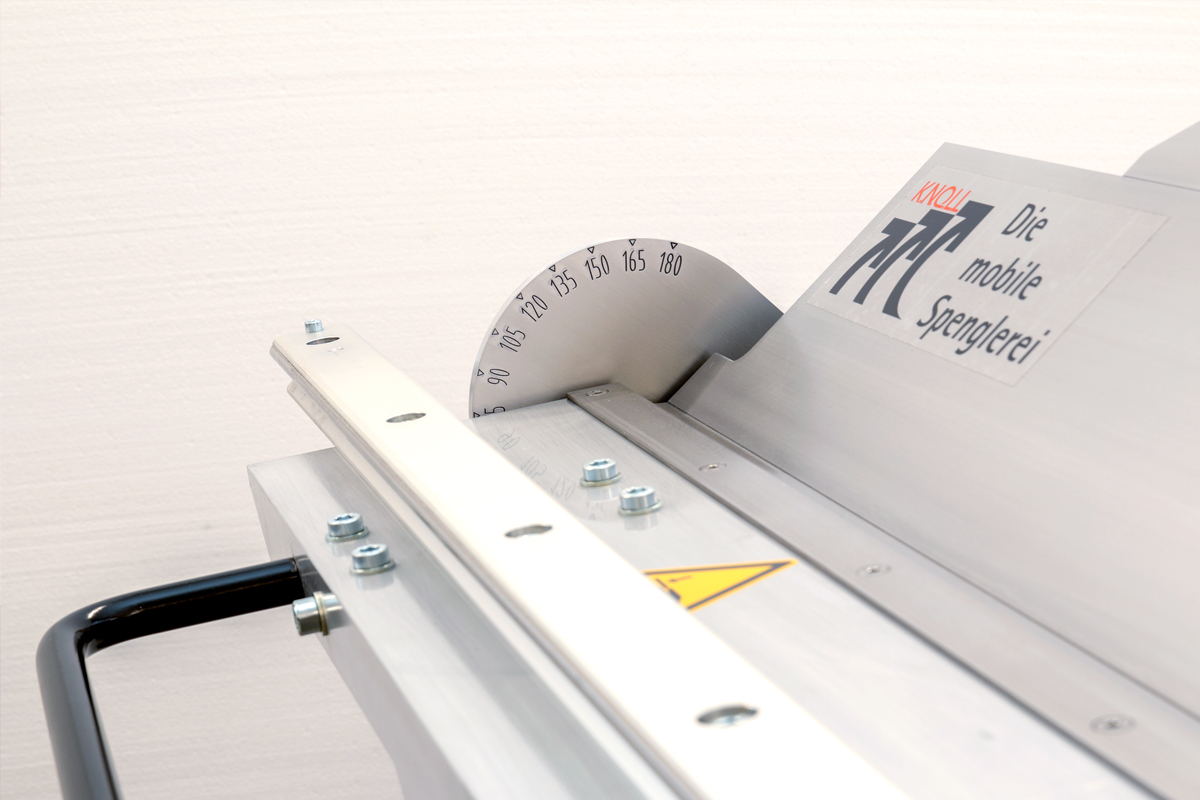

Folding up to 180°

The cleverly designed joints on the folding beam allow for folds up to 180° in combination with the flat stainless steel rail on the upper beam. Folds like hem are finished in one work step without pressing. This saves time and you achieve a high degree of uniformity. This accuracy is of particular importance for the fabrication of façade panels.

Angular Graduation

For the processing of longer metal sheets, the lateral angular graduation can be folded backwards.

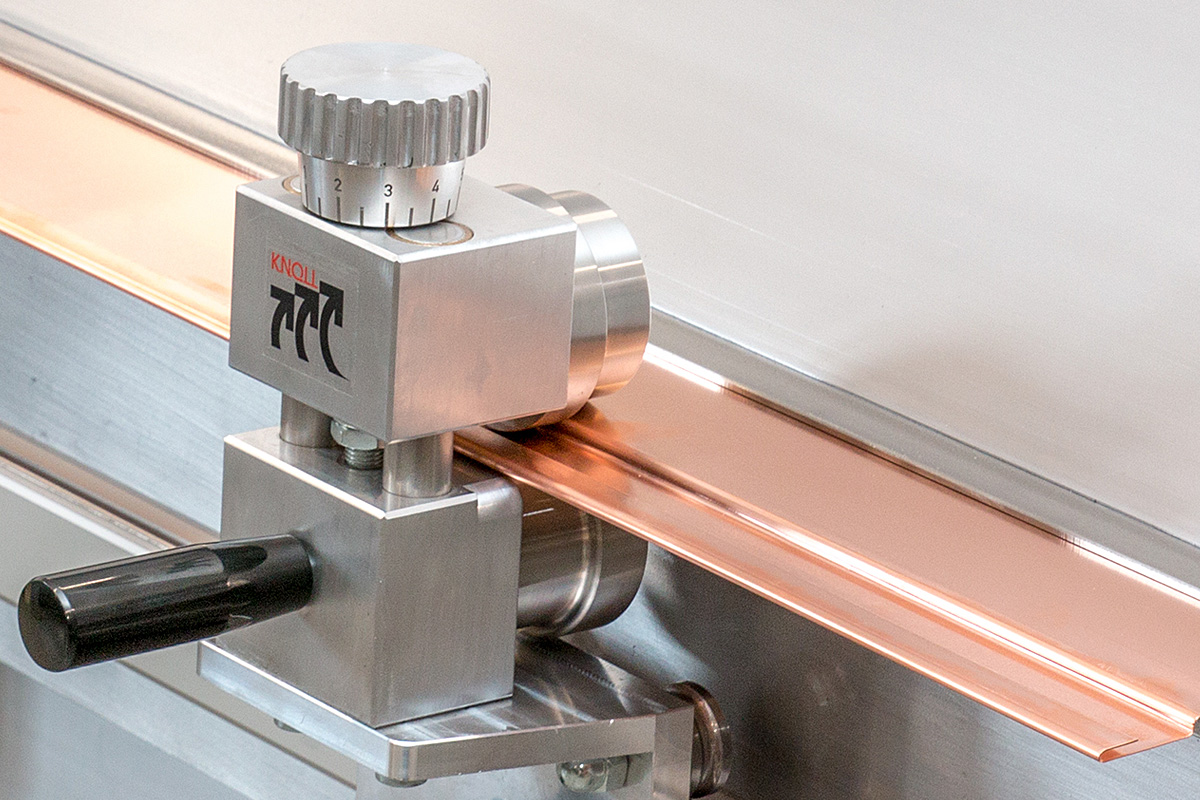

Cutting

The KNOLL cutting head for slitting is attached to the 3.5 m long aluminum folding machine. The double ball bearings ensure high accuracy of the cutting head and thus clean cutting free of burrs. The bearings of the roller cutters as well as the castors are maintenance-free. The cutting head is led precisely on the linear leader and always remains within reach thanks to the parking position at the folding machine.

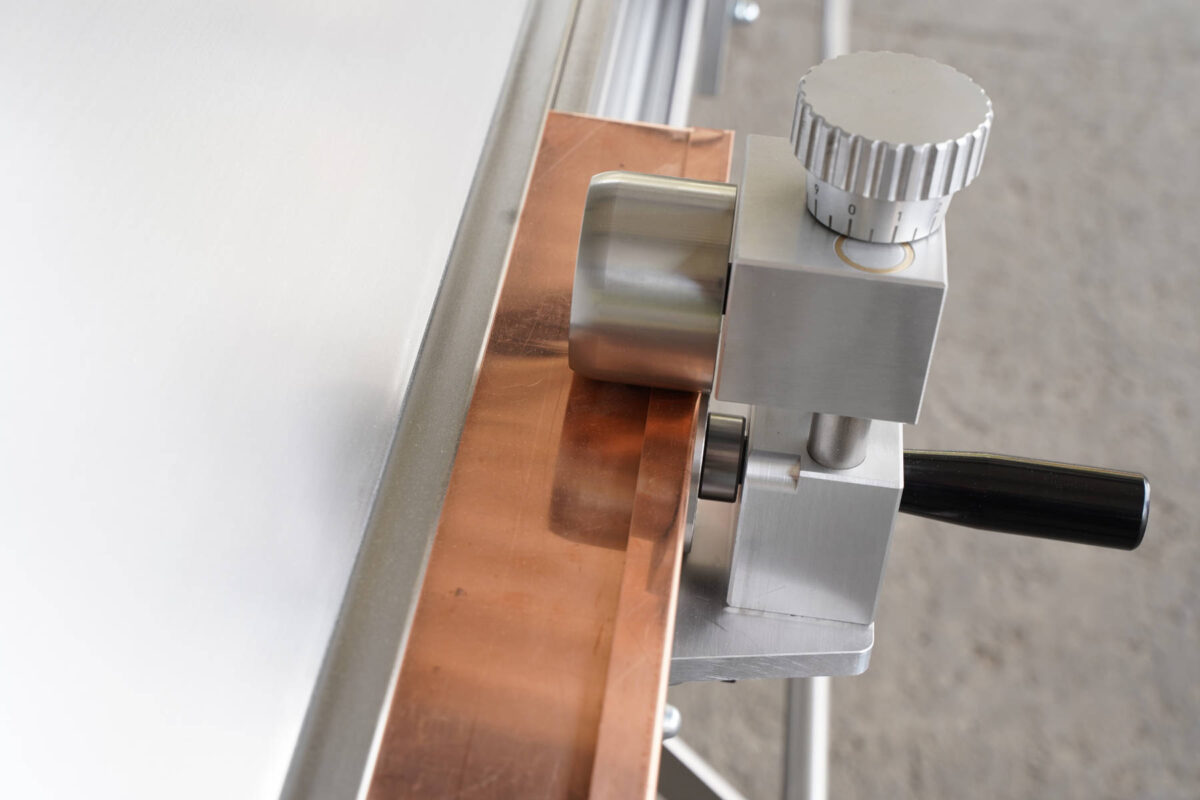

Profiling – fast and easy

With the patented KNOLL profiling head, you can quickly and effortlessly create flush façade profiles directly on the folding machine. The profiling head offsets the metal sheet by the folding height, allowing for precise shaping. These elegant panels can be produced in any width—either as KNOLL slot-in panels or KNOLL hook-in panels, which can be installed from either side. This opens up a wide range of creative design possibilities.

Optional Accessories

Depth control stop with digital display

The KNOLL depth control stop on the folding machine is designed to make single-person operation easy and efficient. Using a hand wheel, the adjustable depth stop can be smoothly moved into position. Cutting and folding measurements are clearly shown on the LCD display, and the reference point can be reset for each new position. With its battery-powered display, the depth control stop ensures precise, millimetre-accurate work every time.

Beading device

With the patented KNOLL bulge coiling device, you can create long, precise bulges directly on the folding machine. The bulge adjustment unit allows for accurate alignment and shaping—enabling both convex and concave curves. This tool is especially useful for producing cover sheets for round window sills, wall cladding, and even ornate baroque-style gables.

Flattening Device

After bending, press the seam flat using the KNOLL seam closer.

Thanks to the spindle adjustment, the pressure can be set precisely and accurately. A double seam can also be closed.

Lead undulating device

The KNOLL lead undulating device enables the production of half-corrugated lead strips with a smooth seam edge. This lead apron is easy to work with: the non-corrugated edge can be neatly folded.

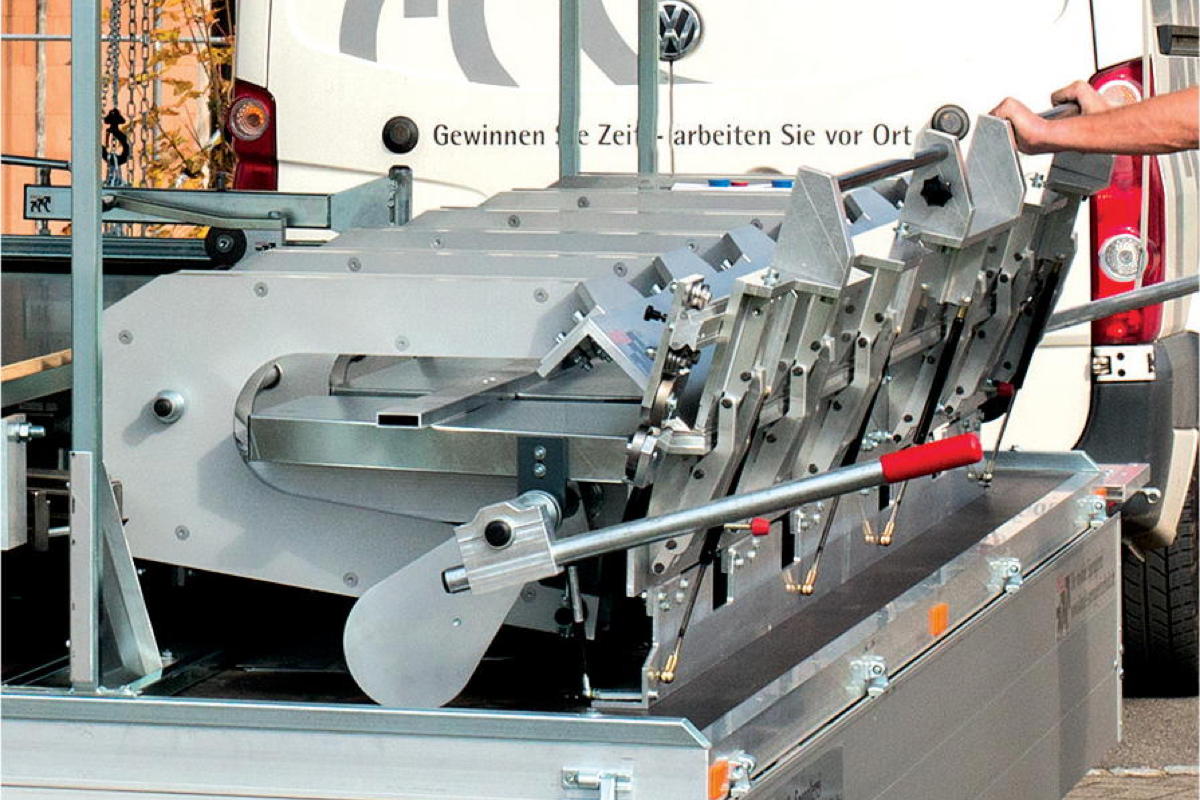

KNOLL offers the optional trailer to turn your KNOLL sheet metal brake into a mobile tinsmith’s work shop!

The sophisticated layout and arrangement of the individual machines and tool components is specifically designed to make sure you have everything you need to complete your work directly on the construction site or in your workshop.

Key advantages include:

-

Integrated workflow: Pull metal sheets directly from the uncoiling trough onto the cutting table for immediate processing.

-

Large, extractable workbench: Offers ample space for cutting and shaping metal sheets on-site.

-

Efficient folding system: Perform 180° folds in a single step using the 3.5 m long KNOLL sheet metal brake, thanks to its special shears joints and narrow stainless steel rail.

-

Accessible tools: The cutting and profiling heads are always within reach, streamlining your workflow.

-

Mobile convenience: Everything you need is compactly arranged for easy transportation and on-site operation.

Decoiling

The decoiling trough also serves as storage and transportation location for metal coils. Lateral coil rails protect the metal against deviating during decoiling. The metal sheet can be decoiled precisely and easily and then is led directly to the cutting table or the profiling machine. We recommend a second decoiling unit for the special version with profiling device.

Cutting – processing

You achieve clean cuts free of burns at the workbench with the cross cutter head and the maintenance-free roller cutter. The cutting table and the workbench come with an angular stop rail with scale and length stop. So the metal sheet can be cut easily, fast and cleanly to the exact dimensions. The spacey workbench can be extracted, e.g. for placing longer metal sheets.