Stay connected with our mailing list to get notified about sales, special offers, new products and business updates!

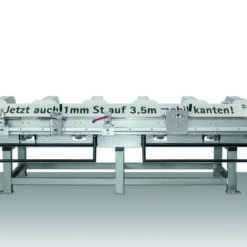

KNOLL Sheet Metal Brake

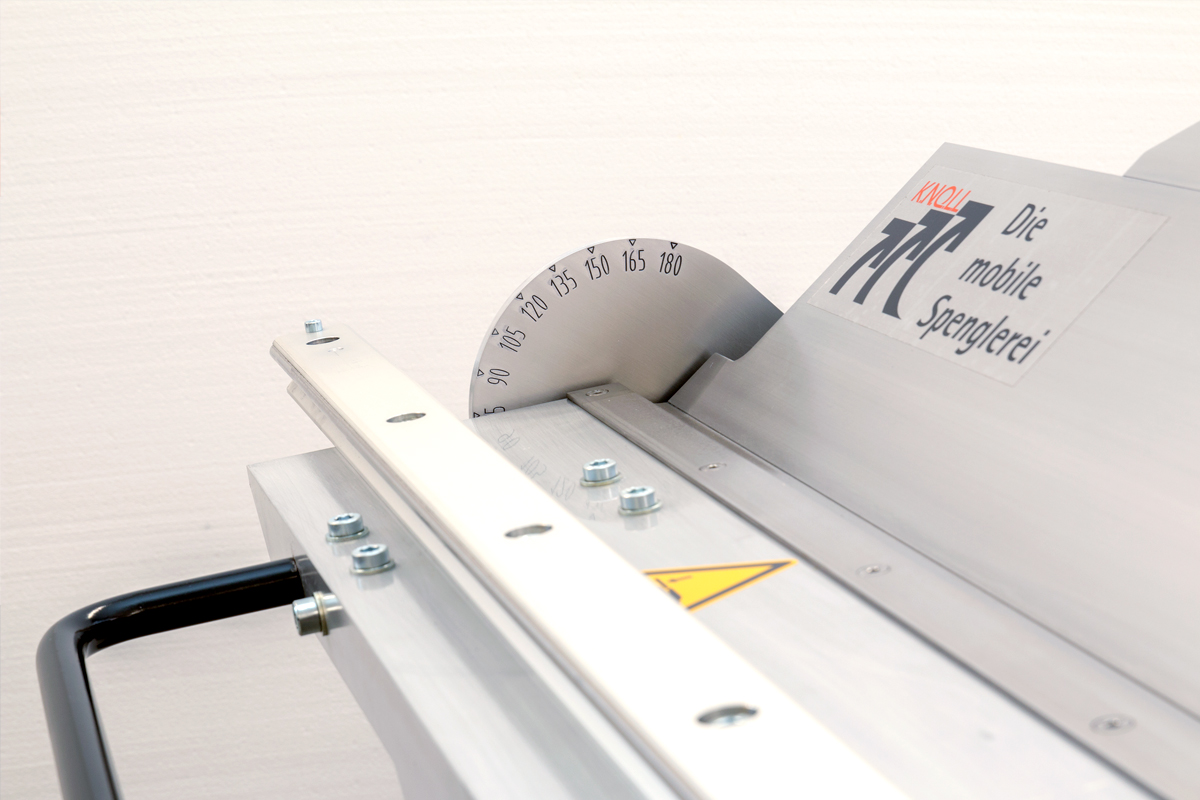

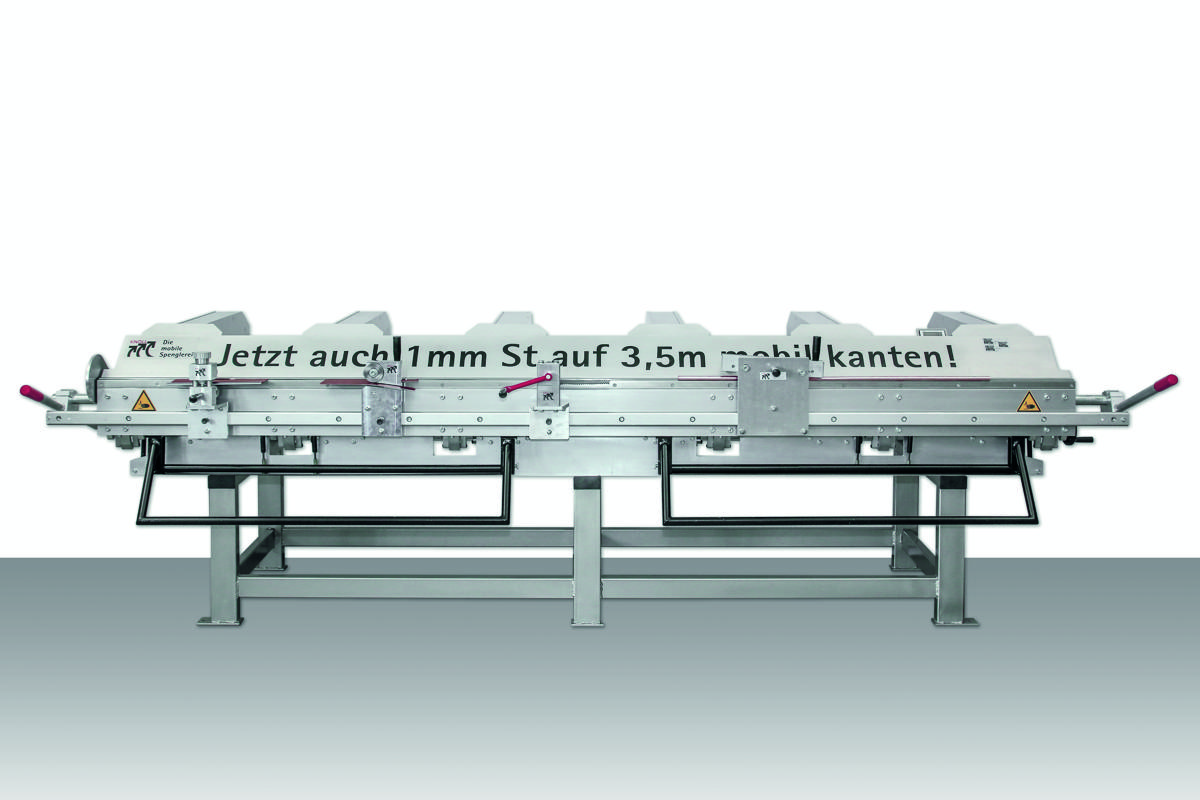

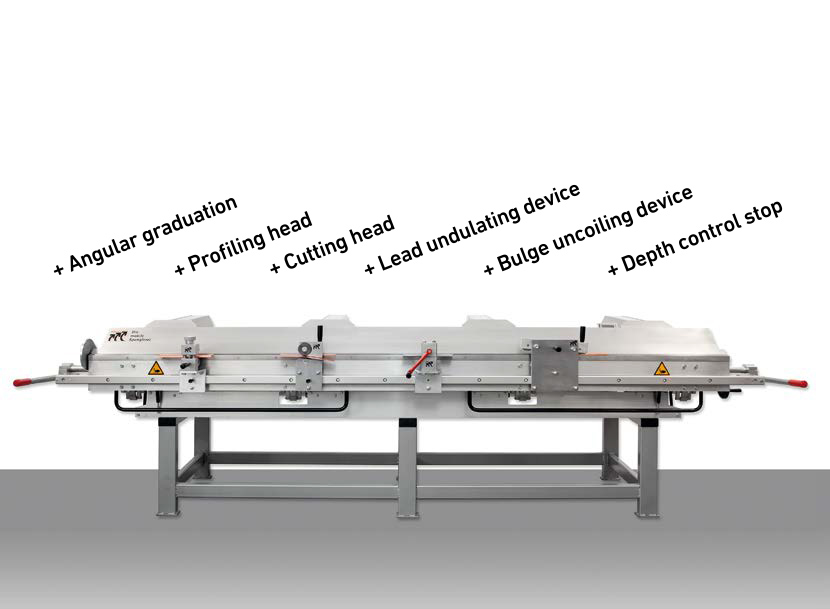

The KNOLL Sheet Metal Brake, with folding up to 180° and 3.5m, is made of a high strength aluminum making it extremely lightweight and very stable. This brake was developed by experienced architectural sheet metal workers and has been successfully tried and tested at thousands of construction sites in Germany and abroad.

The KNOLL Sheet Metal Brake, with folding up to 180° and 3.5m, is made of a high strength aluminum making it extremely lightweight and very stable. This brake was developed by experienced architectural sheet metal workers and has been successfully tried and tested at thousands of construction sites in Germany and abroad.

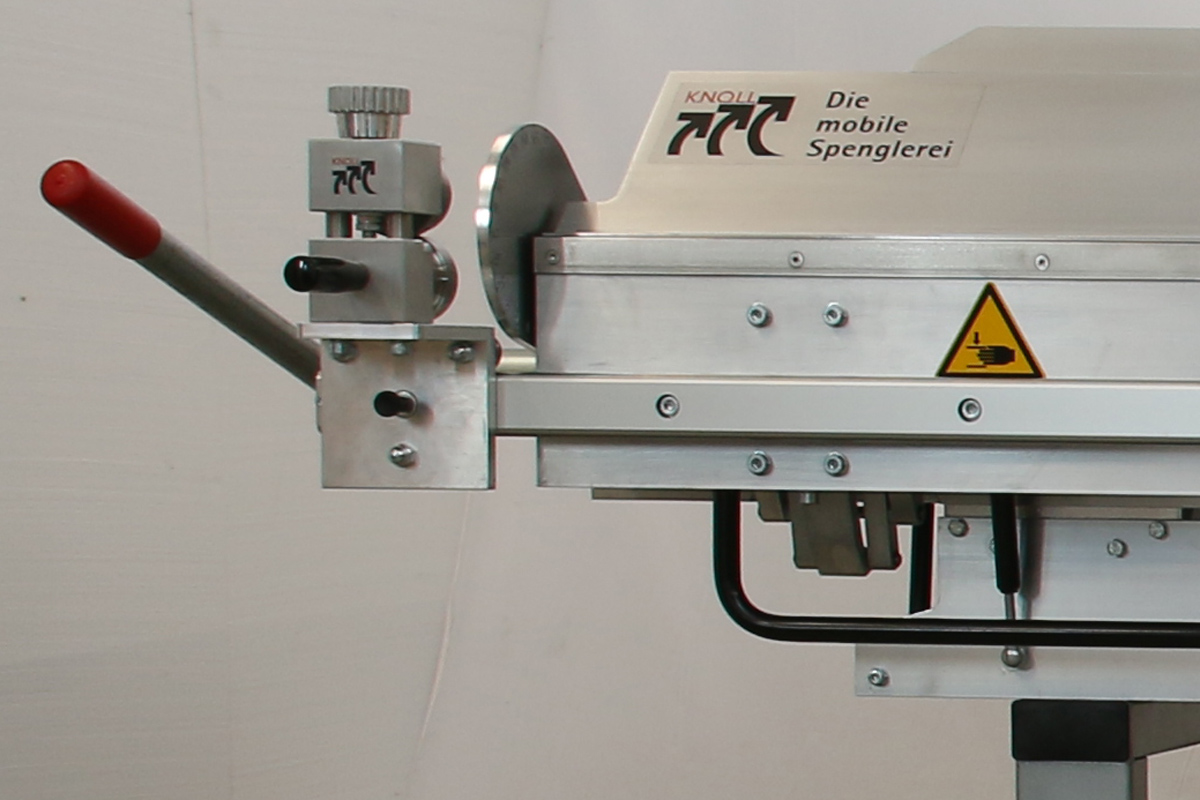

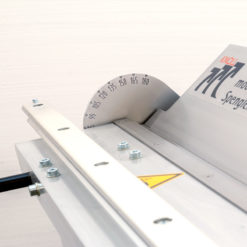

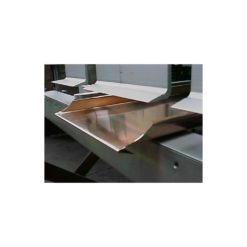

In addition to all cutting and edging work, the now popular and tried and tested KNOLL facade rabbets can be easily produced. The comfortable working height and the arrangement of the devices create an optimal way of working. The constructively refined joints on the bending beam, together with the flat stainless steel rail on the upper beam, enable edging of up to 180°. Hollow envelopes such as water folds are finished in one operation without being pressed shut. This saves you working time and achieves a high degree of uniformity. This is particularly important when manufacturing facade panels.

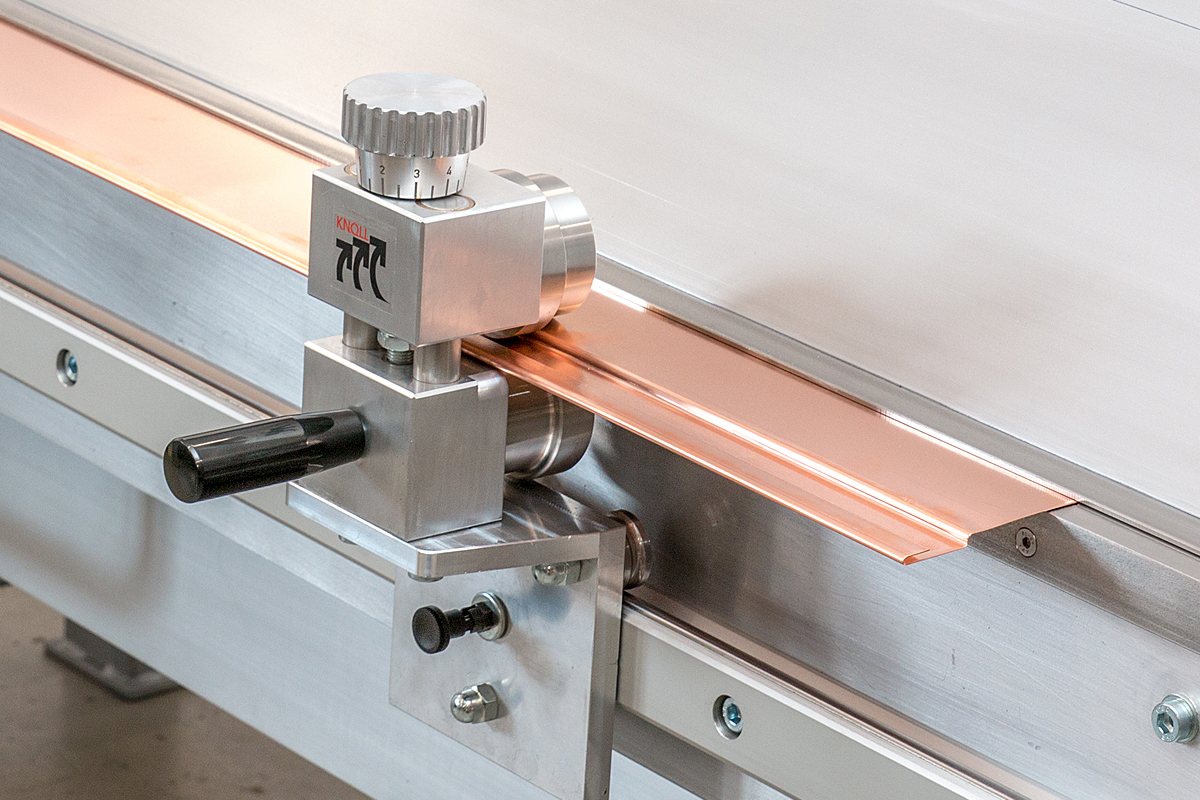

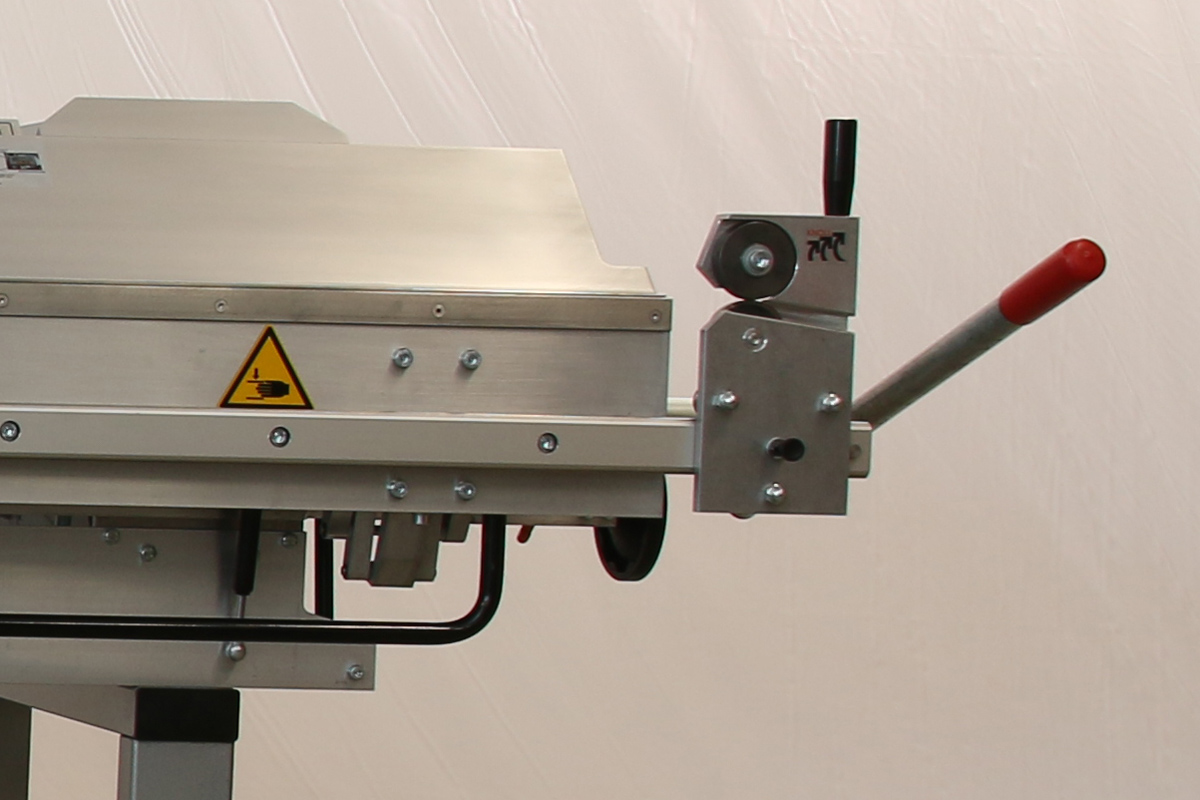

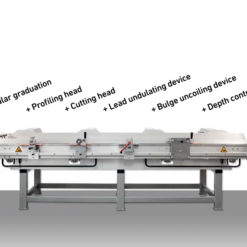

The KNOLL cutting head for longitudinal cutting is located on the 3.5 m long aluminum folding machine. The double ball bearings guarantee the high precision of the cutting head and thus a clean, burr-free cut. The bearings of the roller knives as well as the rollers are WZR maintenance-free. The cutting head is always ready to hand due to the parking position on the folding machine and is therefore ready for use at any time.

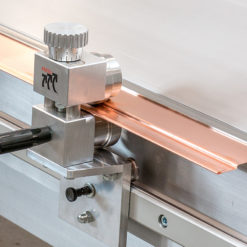

With the patented KNOLL profiling head, you can quickly and easily produce flush facade profiles on the folding machine. The sheet metal is set down by the fold height with the profiling head. These beautiful panels can be manufactured in any width and in the KNOLL push-in fold as well as the KNOLL hook-in fold that can be laid on both sides. This results in countless design possibilities.

Two different bending machines, depending on the application

The KNOLL sheet metal brake – 180° – 3.5 m is available in two different versions. Our four-arm folding machine with an output of Al 1.0 mm, CU 0.8 mm, ZN 0.8 mm, St 0.7 mm is exactly the right thing for the sheet metal worker.

The KNOLL sheet metal brake 6 C was developed for those who need a more powerful machine and still want to work mobile. With reinforced joints and higher material thicknesses as well as six C-arms, 1.0 mm steel can also be bent. Of course, both folding machines are also available as workshop machines with a pedestal!

Technical data of the 4C folding machine

Edge and profiling length: 3.5m

Sheet thickness:

- Al 1.0 mm

- Zn 0.8 mm

- Cu 0.8 mm

- St 0.7 mm

max. bending angle: 180°

- Weight: 320kg

Specifications of the 6C sheet metal brake

Edge and profiling length: 3.5m

max. bending angle: 180°

bending angle max. 155° for sheet thicknesses:

- Al 1.5 mm

Zn 1.5 mm

Cu 1.0 mm

St 1.0 mm - Weight:

- 400kg

- KNOLL offers the optional trailer to turn your KNOLL sheet metal brake into a mobile tinsmith’s work shop! The sophisticated layout and arrangement of the individual machines and tool components is specifically designed to make sure you have everything you need to complete your work directly on the construction site or in your workshop.

Key advantages include:

-

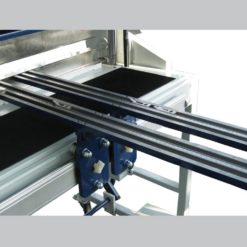

Integrated workflow: Pull metal sheets directly from the uncoiling trough onto the cutting table for immediate processing.

-

Large, extractable workbench: Offers ample space for cutting and shaping metal sheets on-site.

-

Efficient folding system: Perform 180° folds in a single step using the 3.5 m long KNOLL sheet metal brake, thanks to its special scissor joints and narrow stainless steel rail.

-

Accessible tools: The cutting and profiling heads are always within reach, streamlining your workflow.

-

Mobile convenience: Everything you need is compactly arranged for easy transportation and on-site operation.

-

Reviews

There are no reviews yet.